What is the difference between standard soft enamel, cloisonne and die struck

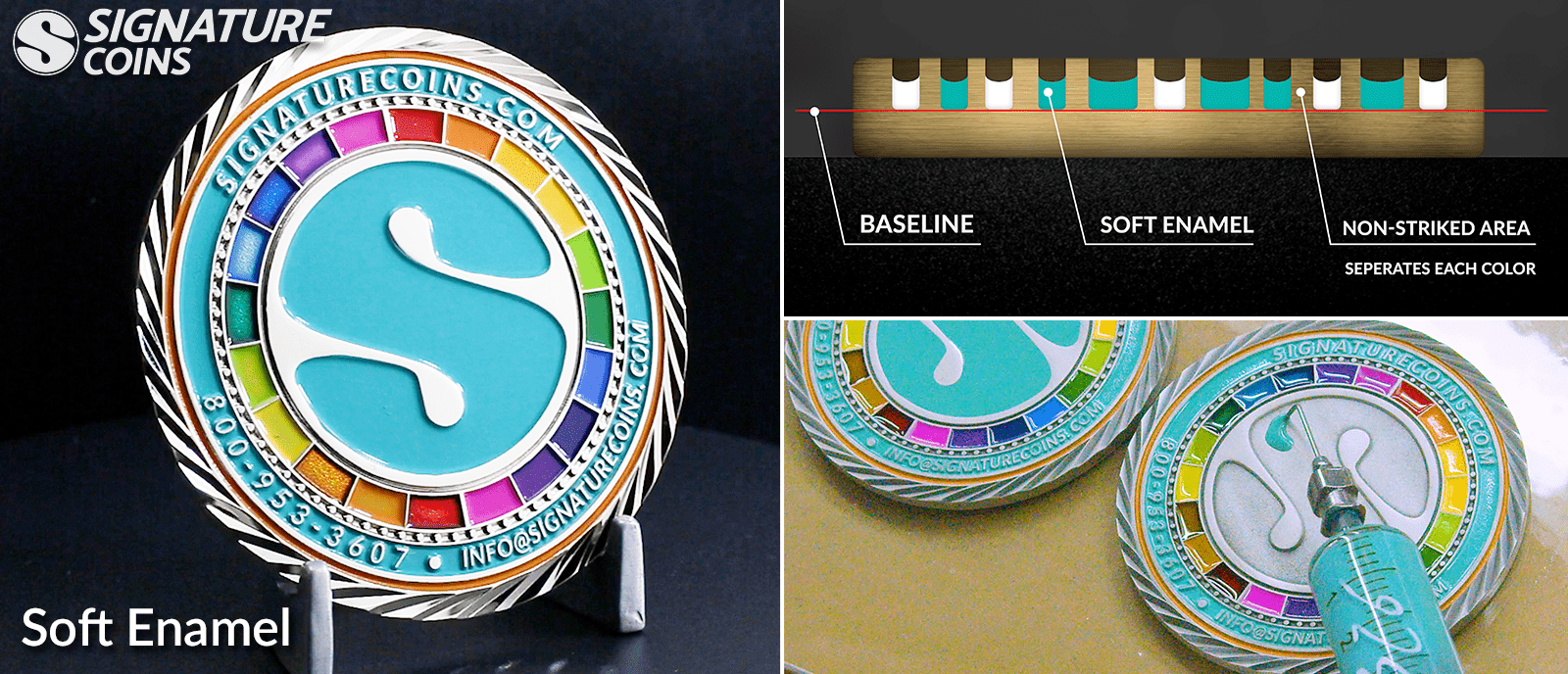

Soft Enamel

After a custom coin is electroplated in your choice of metal plating, enamel paint is added to the recessed areas of your custom coin. The raised metal lines within the design are used to keep the colors from bleeding into one another. Once all the colors are added to these recessed areas, the coins are heat treated to get the paint to dry quickly and to strengthen it against chipping or other wear and tear.

Cloisonné (Hard Enamel)

Just like soft enamel, enamel paint is added to the recessed areas of the custom coin, but unlike with soft enamel, the enamel paint is added until it reaches the top of the metal lines. Each color is heat treated before applying the next color. Metal plating occurs after the color filling, so when the coins enter the polishing process, the final result is a smooth flat surface.

Read Soft vs Hard Enamel Blog Post

Die Struck

Die striking involves using a freshly made coin mold to stamp artwork into brass. Unlike soft and hard enamel, after the metal plating process, no paint is added to the custom coin.

Challenge Coin Customer Reviews

Support Topics

Resources

- Challenge Coin Design Template

- Challenge Coin Checklist

- How to Design a Challenge Coin 101

- Learn how challenge coins are produced

Production

- What is the turnaround time for a challenge coin order?

- How are Challenge Coins made?

- What kinds of paints are used to add color to my coin?

- What is Sandblasting?

- What is Die Casting?

- What's the difference between a cloisonne, die struck and standard soft enamel?

- Where are your coins made?

- How long do you retain my coin mold once an order is placed?

- How Long Does It Take to Make a Challenge Coin?

- How long do you retain my coin mold once an order is placed?

- How do I know when my coin mold is going to expire?